Amazon operations may not be the sexiest part of running a business, but it is vital to driving the profitability of your business and advertising campaigns.

Demand forecasting, purchase order and inventory management, chargeback prevention, and more are all critical to your success as a first-party Vendor on the Marketplace.

At this year’s annual AdNYC event, CPC Strategy’s Amazon Operations Manager Eric Kauss spoke on how Vendors can overcome common challenges to master operational efficiency on Amazon.

Want to learn more about Amazon operations?

View our webinar Using Amazon Demand Forecast to Increase Profitability with our expert Amazon Vendor Operations Manager, Eric Kauss.

View On-Demand

“As a Vendor on Amazon, it’s critical to understand and master the operational side; inventory planning and purchase order forecasting, strategic data options, warehousing and more to boost the efficiency and profitability of your Amazon business.“

Why Are Operations Important for Amazon Marketing Success?

Foundations for Amazon operational success starts with inventory management & planning, followed by purchase order management, warehouse efficiency, and your marketing campaigns.

“You’ve got to get the product and the purchase orders in the system and you’ve got to ship them on time,” explains Kauss.

“And that leads to more profitability from your ads, more profitability from all the operations that you run and fewer chargebacks.”

The goal is to avoid two particular situations where Amazon will not run your ads because:

- Your product is out of stock

- It doesn’t meet the “financial threshold”

Wait, what’s financial threshold?

“It’s [financial threshold] a very vague answer from Amazon, which basically says they think they’re not profitable enough on your product and you’ve got to figure out your costing to make it work for them,” says Kauss.

“Those are two key emails you want to avoid, if at all possible on the Amazon platform because they mean that your marketing strategies are not effective.”

Navigating Amazon’s New Probability Level & Demand Forecast

Let’s start with the forecast. Amazon changed this forecasting about a year ago when they transitioned to the Probability Level Forecast (P-level).

“Most vendors have still lack a complete, 100% grasp on what the data is telling them in the forecast” says Kauss.

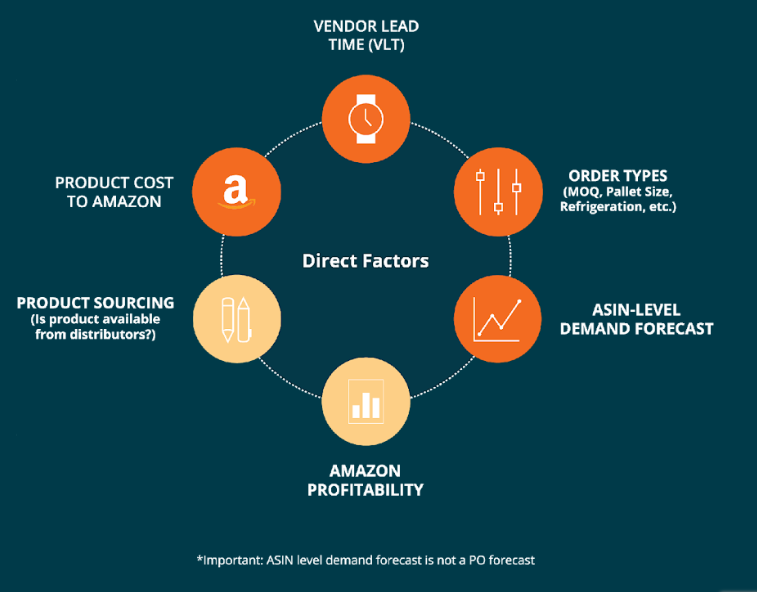

“We break it down into three distinct areas: demand, forecast, and direct factors. These are factors that impact your ability to get purchase orders on a timely and on a weekly basis.”

Amazon Demand Forecast – Direct Factors

1. Product Cost

Product cost is one of the first factors that many vendors fail to accurately account for.

“The reality is that once you set a price for your products on Amazon, it’s not easy to change,” says Kauss.

“You need to make sure that you’re costing your product correctly at the beginning by factoring in the potential changes down the line and understanding that those changes are going to impact your ability to run an ad.”

2. Vendor Lead Time

The second critical component is called Vendor Lead Time, or VLT.

“Amazon tracks every single ASIN on a historical basis takes a look at it and says, on average it takes you 14 days to get me this inventory,” says Kauss.

“Amazon can be vague about the timeframe. My feeling is it’s somewhere between 30 to 60 days is what they’re tracking.”

According to Kauss, Amazon uses that historical data (VLT) to inform your demand forecast.

“Amazon might say, that over the next four weeks, you need 1,000 units based on the history. Your VLT says it takes 14 days for you to receive it, so Amazon writes a purchase order for 500 units, that’s why sometimes your purchase orders don’t match demand forecast.”

Kauss explains that there was a time when Amazon used to order 7-10 days of safety stock when they bought inventory. They no longer do that.

“They’re expecting you to hold the inventory, you to hold the management of the inventory risk and for you to take the financial burden of carrying that inventory. It’s a big burden. But you’ve got to figure out how to do that.”

3. Amazon Profitability

Amazon profitability is in Amazon’s realm of control, explains Kauss.

“It’s hard to get them to hold your price. The reality of it is that you’ve got to cost your product correctly,” says Kauss.

“This means accounting for Amazon’s price fluctuations. Which is why we work with clients to understand those challenges and manage that pricing.”

Amazon Demand Forecast – Indirect Factors

Indirect factors are the factors that influence demand forecast but do not directly contribute to issuing the purchase order.

These indirect factors include:

- Traffic to ASIN’s Page

- Promotions

- Stock Availability

- Product Setup

- Sales Price (Amazon Controlled)

1. Traffic to the ASIN Page

“The demand forecast is created by demand and traffic to the detail page,” says Kauss.

“This includes impressions and glance views to the page.”

“The most confusing part for vendors is that that traffic is measured regardless of whether the customer buys from your or a third-party seller. Amazon has no way of parsing data that attributes that demand to you or another seller.”

“For example, when you get a demand forecast but a third-party seller had the buy box for three of the seven days last week, that demand is included in your forecast. We work with clients to help parse that data to have a more accurate forecast.”

2. Promotions

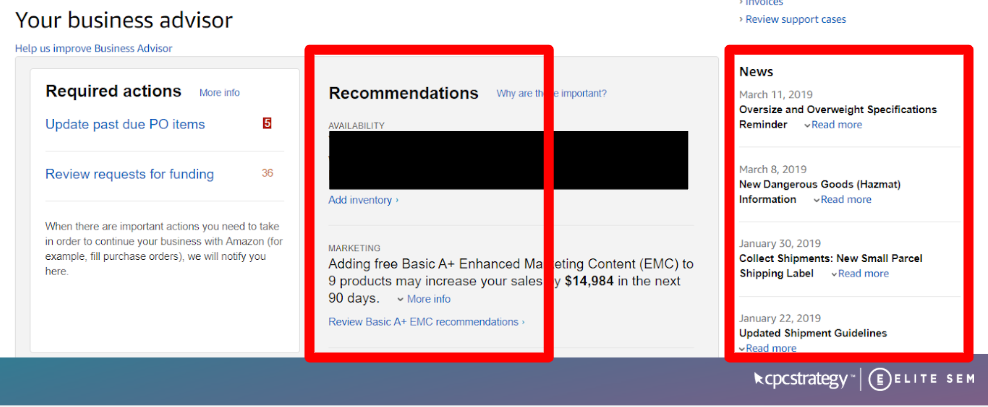

Promotions, without a doubt, drive traffic, explains Kauss.

“Promotions need to be a part of your Amazon operations. Amazon has done a very good job on the recommendations within the Vendor Central homepage.”

“The one part about that is that most vendors are missing is they think that they can only do the recommended ones. We strongly recommend you put your own promotions in and you just decide what works for you.”

“Don’t let Amazon dictate totally what promotions you’re going to be doing. Use Your best judgment about what you want to promote and obviously Amazon’s going to ask you to fund that.”

Demand Forecast – Market Factors

Another indirect factor is your sales performance, which includes your sales over the previous 13 weeks.

“If you sell seasonal products, then sales history from last year are also part of the equation,” says Kauss.

In the end, all indirect factors influence the direct factors that ultimately determine your purchase orders from Amazon.

“Now, does it always match up perfectly? The answer is no,” explains Kauss.

“However, if you find the right ways to make this equation work for you, you will have more visibility into your forecast, your purchase orders, and more control of your business on Amazon.”

Understanding the Amazon Forecast and Inventory Planning Report

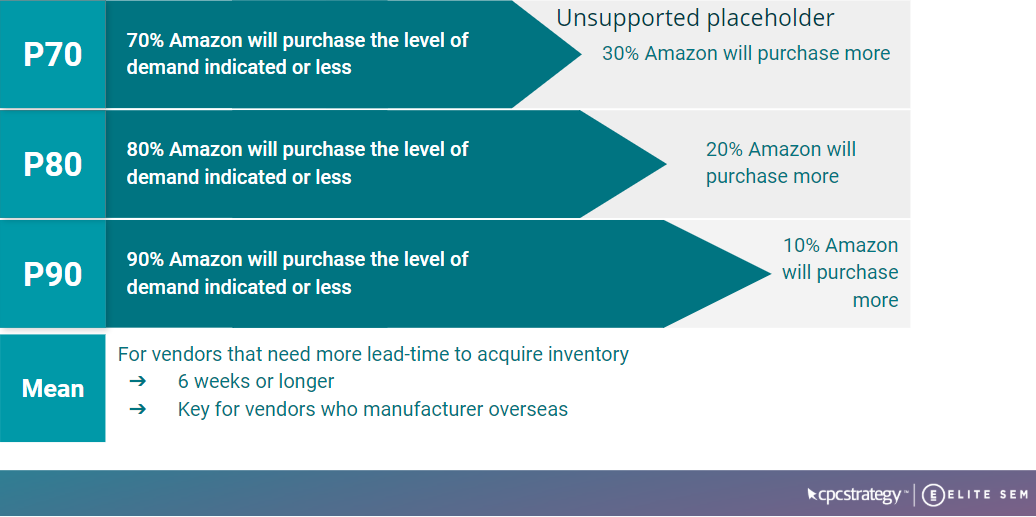

The Probability Forecast is a rolling 26-week estimate as close as possible to actual customer demand.

How it works:

- Presented in different probability levels giving vendors a choice of how to stock inventory based on risk tolerance

- No longer calculates safety stock into demand

- Continues to use Vendor Lead-Time (VLT) for the calculation of actual purchase order quantities per week

- Does not represent a purchase order forecast

“This [graphic] tells you if you’re going to buy the piece 70-P forecasts, they all buy that level 70% or less of the time. 30% of the time they’ll buy more at P-80 or P-90 and it goes up from there,” says Kauss.

“The mean forecast is used predominantly for overseas production where if you have to do something ahead of time.”

It’s important to understand that the probability forecast is driven at the ASIN level, and not the parent ASIN level, notes Kauss.

“So you need to make sure that you understand what inventory risk your financial teams are willing to take. Because if you buy the P-90 forecasts on every single ASIN, you’re going to have a lot of inventory in your warehouse hoping a purchase order shows up.”

“We don’t divide it into percentages because in some cases the top tier could be only five ASINS. Those are the ones you want to protect and you buy those at the P-90 level because that’s going to give you the most inventory in the building and you’ll be able to manage that inventory from there.”

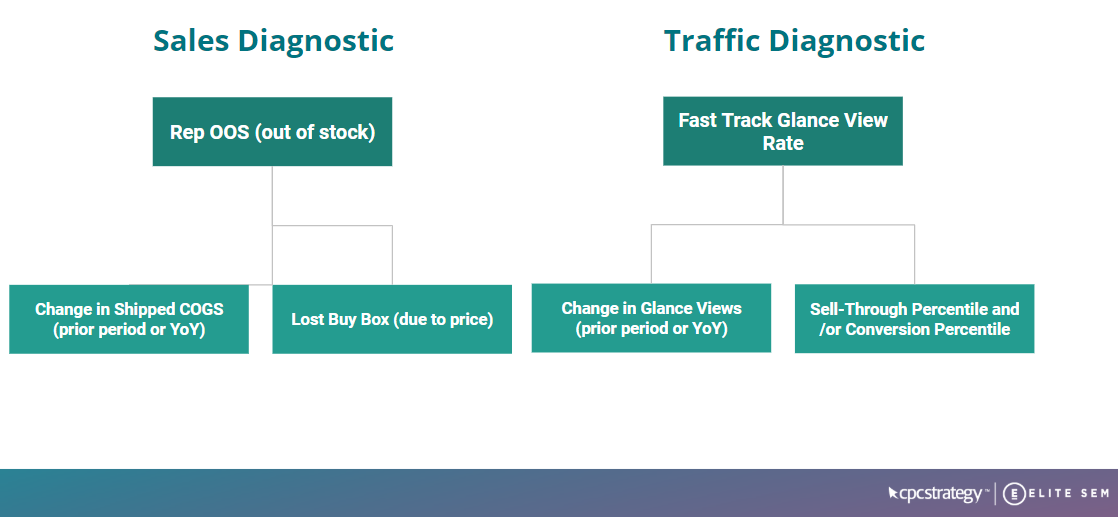

The Two Key Metrics Impacting Amazon Demand Forecast

In addition to the direct and indirect factors discussed above, there are also two key metrics that impact your demand forecast: sales diagnostics and traffic diagnostics.

Rep Out of Stock

“Your rep out of stock is going to clearly impacted because if you don’t have inventory, you can’t have a sale. You’ve got to have inventory at Amazon,” says Kauss.

Change in Shipped COGS

“You want to take a look at your change in shipped COGSA in the prior period and now.”

“Why a year over year? Because that tells you whether you’re growing or not growing that ASIN at a specific level. And whether you want a plan to move that out of the category that you’re moving in,” says Kauss.

“If you had it in the 80 percentile and then you decide, ‘well wait a minute, this is really trending. I’ve got to move it up to the 90 percentile and make it a core ASIN,’ but then you end up losing the buy box — you’ve got to look at your profitability.”

“There are some times that from a profitability perspective, you may want to let it go.”

Change in Glance Views

The fast track glance view rate is the rate that your inventory is in stock for Prime Shipping by Amazon.

“They’re in stock and what percentage rates you’re at. We work with our clients for an 85% goal on that number. We’d never worked towards 100% goal because if your business is growing and it’s organically growing or it accelerates past organic, you won’t be able to get to 100%. It’s impossible because Amazon has had a lagging indicator.”

“That’s because Amazon won’t buy enough inventory ahead of time so you’re never going to get there.”

Changes in glance views come out on a weekly basis.

“For the most part, you should look to see what the history of an ASIN is on a monthly or quarterly basis. What’s happening with it, is it getting better? Worse?” asks Kauss.

“Is an ASIN in that was your number five ASIN last year with glance views that are down 40% year over year? Is there a need for a campaign? Is there a need for something to support that from a promotional perspective?”

Sell-through & Conversion Percentile

“The sell-through percentile actually comes off of the inventory health report,” says Kauss.

“You’re selling your inventory each week, but for those of you who have Ara Premium, the metric is called the conversion percentile. Amazon’s very vague about what converts, what their true algorithm is for conversion. The reality is on an overall basis, Amazon does not tell your conversion rate. If you look at it, they tell you it grew, it went up, it went up 4% over the period before or not. But the conversion percentile may be one of the metrics that I think has become most important for understanding how your products perform from a conversion level.”

“If you’re on basic, it means that if you have a 90% conversion percentile on an ASIN, it means you convert better than 90% of all the ASINS in the category and only 10% of them convert more than you.”

Why Proper Demand Forecasting Is Crucial

Everything works together to contribute to your operational health, says Kauss.

“Purchase Order Management, warehouse efficiencies, advertising, increased sales growth, expanding product offerings, content set up, and finally back to purchase order management because you set it up correctly, you have the inventory available and it keeps going around and around.”

“You want to have a consistent flow of understanding the Amazon operational impacts that come from the demand forecast.”

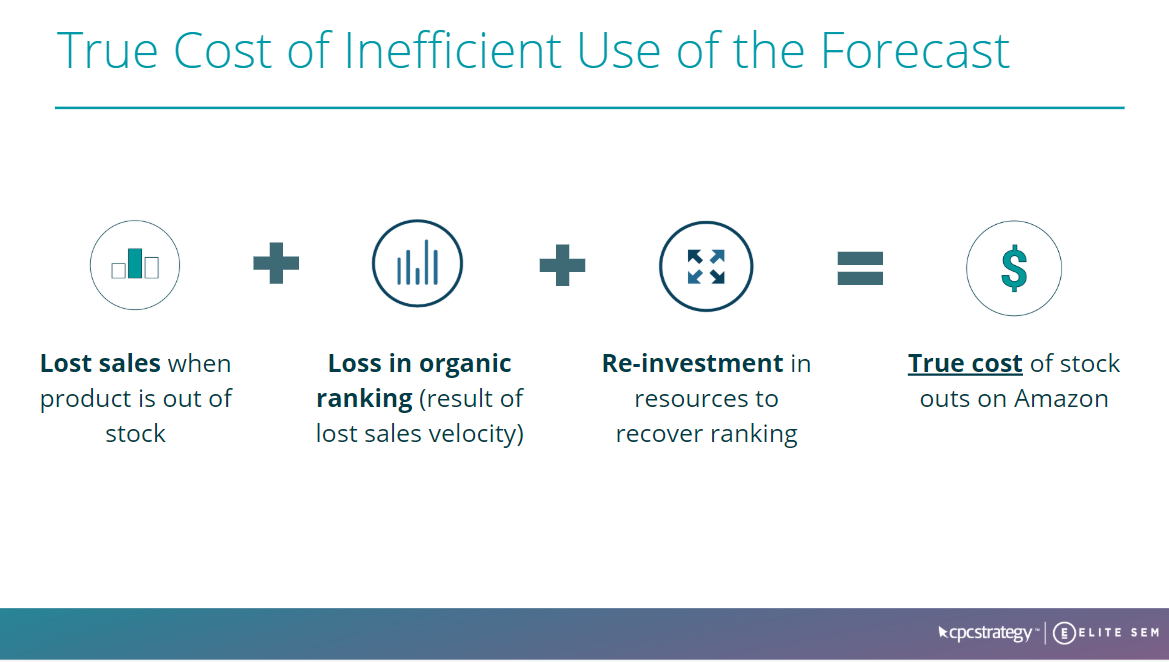

The True Cost of Amazon Operations Inefficiency

The costs of not mastering your Amazon operations can be fatal, explains Kauss.

“Everybody says, well, I didn’t have the inventory so I lost a sale for a $35 item. That’s not correct. Besides the sale, you lost your ranking, your organic ranking, and resources in advertising campaign and promotion.”

Strategic Data Options to Utilize Forecast Data

There is more than just one way to look at the Demand Forecast Data, explains Kauss.

“You can manage your business on the Amazon platform. For example, you can divide your inventory up into three tiers, deciding which of the P-levels you want to use, and then buy the inventory or quarterly to support that.”

“The other way to use the report is to track what’s true, what’s happening on a week-by-week basis against the demand forecast. ‘Amazon told me I needed a hundred units but the only ordered 50’ and that continues for over a 13 week period means you can then plan your inventory accordingly going forward on that ASIN,” Kauss continues.

“There may be outliers where you’ll say they should be ordering more and we’re gonna plan this promotion so I’m going to buy more inventory. But on a day in, day out basis, you should track your inventory and track your purchase orders and see what happens against the demand forecast.“

Purchase Orders Vs. Demand Tracking

- Demand forecast → previous 13 weeks sales; compare these to actual purchase orders

- Track the demand vs. purchase orders on a weekly basis

- Not all ASINS are the same

- Amazon is still expecting a 100% confirmation rate

Back Up Planning: Direct Fulfillment / Dropship

“Now not everybody can do direct fulfillment. If you can do direct fulfillment, you should try to be part of that. The reason is is that if you’re able to do direct fulfillment, which is shipping order to a customer instead of the Amazon warehouses, shipping orders to a customer, you’re going to save a sale,” says Kauss.

“If you have inventory and that drives traffic and that drives demand and that keeps sales going and you want to do it. It is also a great place to launch new products.”

“As soon as you’re in stock, you tie it into an advertising campaign, promotion, whatever it may be. It drives traffic to the page which builds the demand, which will eventually force Amazon to write a purchase order. That’s how the cycle works.”

There’s an operational cost to this. Your warehouse has to be ready to not only ship bulk what they have to ship individual orders. If you have dropship back up and Amazon runs out of inventory, all you are to the customer is another Amazon Fulfillment center.”

Advantages of Direct Fulfillment/Dropship

- Vendor’s inventory acts as a backup

- Make a vendor’s entire catalog available

- Build demand for new products at a quicker pace

- Protect sales

Purchase Order & Chargeback Management

Chargebacks are a reality for every business, and there’s a good chance that most people at first don’t understand them.

“Chargebacks will happen and you need to find a way to work with your operations team to address these. We do this on a constant basis,” explains Kauss.

“Most Vendors have a three-day window to ship a product. Some have a seven-day window. It’s hard to get it out, particularly when you ship 50,000 units out. It’s really hard to do. You’re expected to do it. And if you don’t do it on time, they charge you back.”

“And the major reason for the chargeback is not that it doesn’t get out the door correctly, but that somebody didn’t manage the purchase order correctly. Whether it’s from an EDI perspective, communicate with Amazon that the product had left the door that it was coming and everything that needed to go with it,” says Kauss.

“Purchase Order management should be a major focus if you want to keep your chargebacks low.”

Purchase Order Management:

- Review procedures for processing purchase orders in a timely and efficient manner

- Review procedures use of PO

- Acknowledgment Status and Codes

- Understand the backorder process and the ramifications/costs of doing so

- Monitor shipping information to update delivery dates to Amazon

- Confirm the information is being transmitted in a timely manner to Amazon

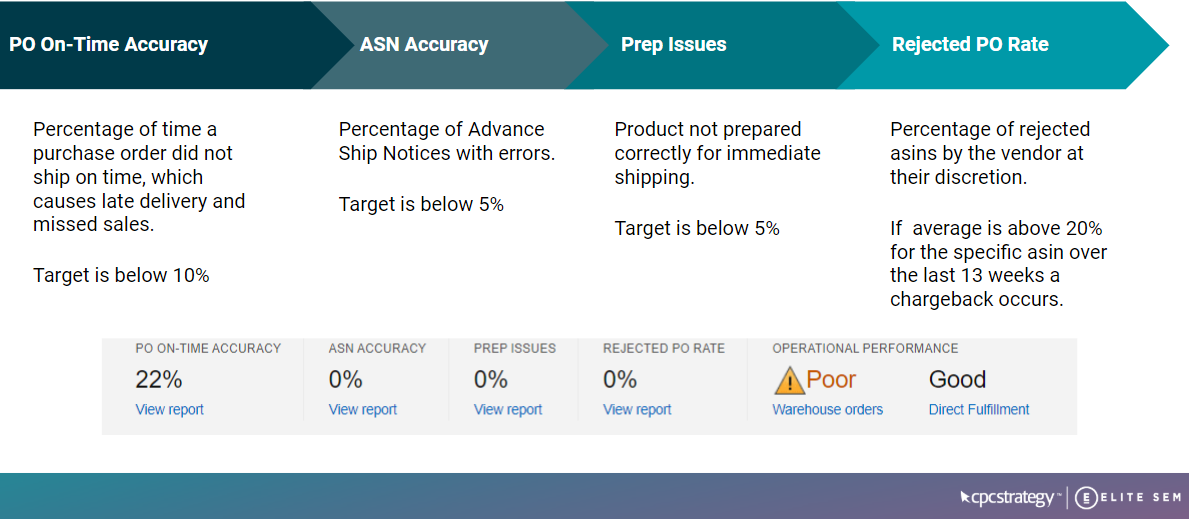

Amazon Warehouse Operation Efficiencies

The dashboard below displays the four key areas that show up on everybody’s report.

Whether it’s shipping on time, making sure you’re communicating to Amazon that products are coming, your shipping boxes are properly prepared, or rejecting Amazon’s POs — all are factors that determine the operational health of your Amazon business.

“It all comes down to making sure you’re handling the purchase order correctly,” says Kauss.

“That means PO management and staying on top communication with Amazon on all of your orders and shipments.”

Final Takeaways For Efficient Amazon Operations

Mastering your operational efficiency is key to growing your profitable Vendor business on Amazon.

Here’s how you can improve your Amazon operations:

- Understand the Complexity of the Forecasting System

- Know the Key Metrics Impacting Demand

- Analyze Alternative Strategies for Operating on the Platform

- Review Correct Procedures of PO Management

- Analyze Current Chargebacks for Action Points

Want to learn more about Amazon operations?

CPC Strategy’s Amazon Vendor Operations Program

House of Jack Co. & CPC Strategy Team Up To Increase Amazon Sales 101%

How Will the New Amazon Demand Forecast Impact Vendors?

The Amazon Hybrid Model: Take Control of Your Growth on Amazon

The Amazon Ecosystem for Vendors, Explained | 2018 Edition

You Might Be Interested In