How Amazon's Supply Chain Strategy Works

Retailers can learn a lot from the Amazon supply chain strategy – especially since the company has decided to launch its own delivery network, a la Fedex and UPS.

In the following article, we will discuss:

Jeff Bezos and his organization have found a way to optimize nearly every piece of the supply chain puzzle – from warehousing and inventory management to delivery times and prices.

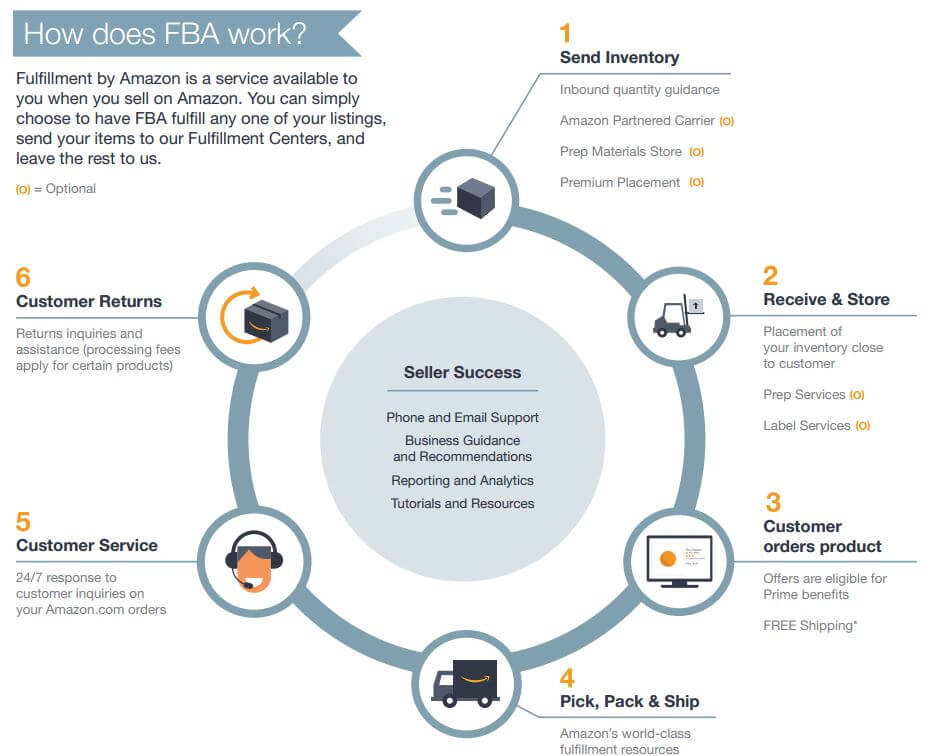

Sellers who sell on the Amazon Marketplace have different fulfillment options to choose from. Sellers can choose whether they want to handle fulfillment or let Amazon sort, package and ship products through their own fulfillment centers.

As a third party seller selling on the Amazon Marketplace you have the option to use Amazon’s fulfillment services:

Below is an image that describes how Amazon handles every aspect of FBA:

They’ve even added drones, robots and other high-tech strategies into the mix.

The result? It’s made Amazon one of the most popular – and most profitable – retailers in all the world.

Recently, Amazon has made a shift in how they are communicating inventory demand to vendors with the addition of a new feature: Probability Level Demand Forecast (available in both ARA Basic & Premium).

Vendors are now being forced to make some critical decisions that will directly impact their stock levels for Amazon (and potentially impact the success of their entire business).

Although Demand will continue to be based on glance views, sales history, and projected demand for planned promotions, the forecast will now have three new probability forecasts for the vendor to choose from including:

P70 – Means there is a 70% chance Amazon will purchase the level of demand indicated or less and a 30% chance they will purchase more.

P80 – Means there is an 80% chance Amazon will purchase the level of demand indicated or less and a 20% chance they will purchase more.

P90 – Means there is a 90% chance Amazon will purchase the level of demand indicated or less and a 10% change they will purchase more.

Now, let’s break down the individual pieces of the Amazon supply chain strategy including:

– Warehousing

– Delivery

– Technology

– Manufacturing

A big part of Amazon’s success lies in its expert warehousing strategy, which ensures products are easily accessible from pretty much everywhere in the world.

All the company’s warehouses are strategically placed near big metros and population hubs, and inventory is spread amongst them to ensure supply can meet demand. There are even mini-warehouses in smaller areas to ensure orders can be sent and delivered fast, no matter what is being purchased.

Warehouses are also optimized internally. Each with five unique storage areas, the organization strategy allows team members and pick-and-pack robots to pull products almost instantly and move them toward delivery.

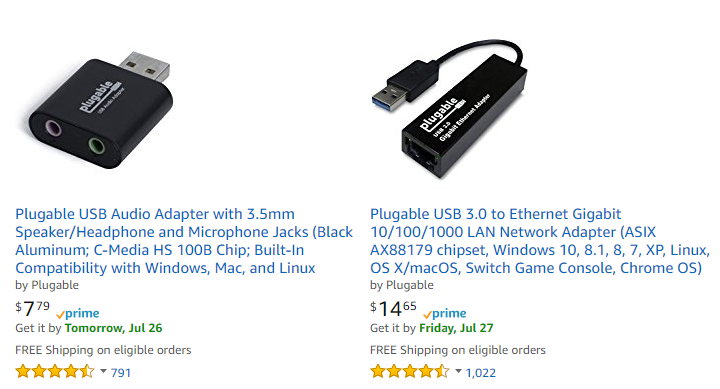

Plugable Technologies, founded in September of 2009, is just one example of a brand who was able to successfully established its goal of “building a better device company” – largely thanks to the implementation of FBA seller strategy & automation.

““Plugable bet on Amazon and FBA from day one. I wanted to focus on technology and customer support and not have to worry about selling and the logistics of individual customer orders.” I needed our higher investments in product quality and support to be rewarded through positive reviews, so it would all be financially sustainable.”

Bernie Thompson, Plugable Technologies

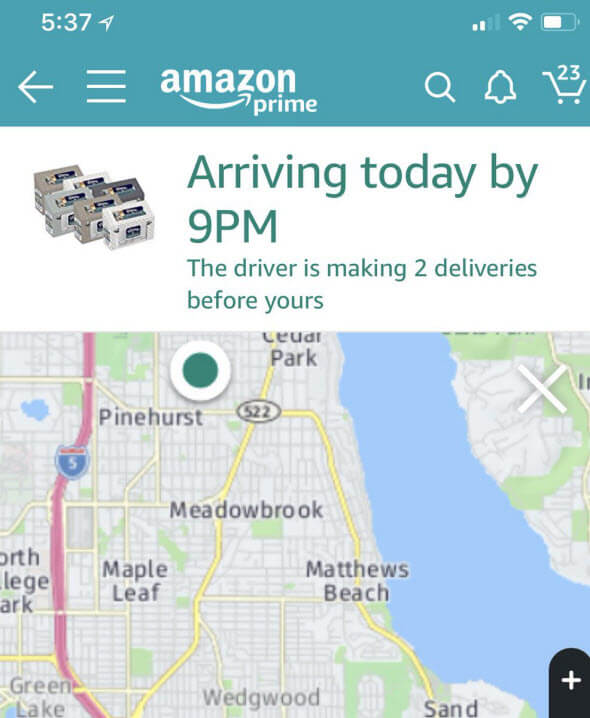

One of the biggest differentiators between the Amazon supply chain strategy and other online retailers’ is the plethora of delivery options offered.

Sure, those options include the free, two-day Prime deliveries and even the Prime Now option, which gets products from point A to point B in two hours of less. But what’s the bigger game-changer?

That’s the number of ways in which Amazon can make those deliveries happen.

Amazon employs a whole host of strategies – from more traditional to super high-tech – to get its products out in lightning-fast times and all over the world.

There are drones that land in your backyard or on your roof, there are Amazon-branded trucks and delivery vans and there are even deliveries by bike in certain areas.

The retailer also leverages existing delivery routes via Fedex and UPS, too.

These wide-ranging strategies allow the company to get orders out faster, easier and more efficiently to basically everywhere in the world – even remote and rural areas not served by traditional options.

“Many online shoppers already have a deep loyalty to shopping on Amazon and are Amazon Prime members, which makes them much more likely to click on products being advertised by Amazon. If a shopper knows they can get free two-day shipping and the unmatched customer service experience they get with Amazon, they will often choose them over lesser-known retailers.”

– Pat Petriello

The Amazon supply chain management approach is to embrace technology. The company utilizes countless automation and robotic solutions, both to pick and pack orders as well as stacking and storing inventory.

These tools not only up the company’s efficiency and delivery speeds, but they also cut down on warehouse and staffing costs – freeing up funds for other logistics or supply chain needs.

Amazon still allows third-party sellers, but the company seems to have learned that many of those third-party products can be made for much cheaper – and more profitably. The retailer has taken to manufacturing its own lower-cost products, as well as white-labeling products from other sellers.

Amazon offers branded lines in everything from household products to pets to babies, and the list of labels just keeps growing. This allows Amazon to own the whole lifecycle of its products – from creation to marketing to storage to shipment.

Though Amazon might have one of the most well-tuned supply chain strategies in the world, the company’s never one to sit stagnantly.

What about sellers who want to expand internationally?

Amazon operates 11 online marketplaces (websites) worldwide, allowing sellers to grow their business internationally, independent of where their business is physically established.

With Amazon, sellers can introduce their brand and products to millions of customers in Amazon’s marketplaces as seen below:

North America

Europe

Asia

These marketplaces represent many of the world’s largest e-commerce opportunities. When you register to sell in one of these Amazon marketplaces, you gain immediate access to customers who know and trust the Amazon buying experience. There’s a lot of advantages to expanding sales to one or more of Amazon’s marketplaces. One of the biggest benefits is that sellers can leverage the Amazon brand without having to foot the upfront costs of building business name recognition on their own in a brand new sales environment.

“Amazon’s European Fulfillment Network (EFN) is a powerful way to reach customers across Europe from a single marketplace account,”

Pat Petriello

“Amazon will handle picking, packing, and shipping your products across Europe from a single pool of inventory without you having to worry about importing or customs for each nation within the EFN.”

“For instance, you can ship your inventory into Amazon Fulfillment Center in the UK and any customers across Europe can have that product shipped directly to them. You can also use that pool of inventory to list the product on other European sites such as .de or .fr as long as you list that product in the native language of that region’s marketplace.”